Finish supplier Osteks GmbH can be found between the two Scheibenberg and Zwönitz sites in the Ore Mountains area.

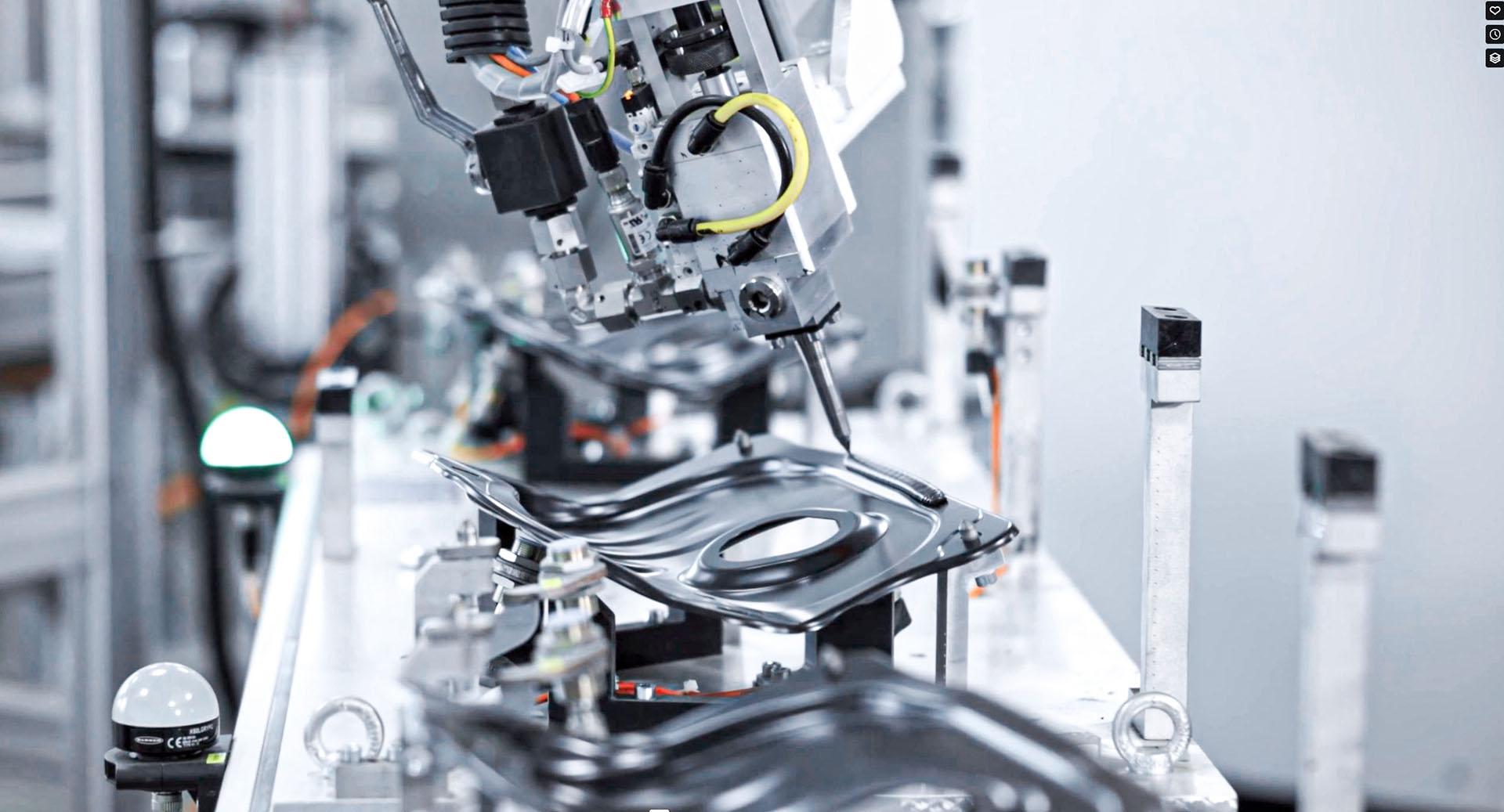

Manufacturer: Knipl

Robot-assisted application of 1-component PUR foam “FIPFG (formed in-place foam gaskets)” for sealing or avoiding noise

Material: Sunstar Penguin Foam 3157 / single-component polyurethane elastomer, solvent-free, heat-curing, closed-cell, flexible

Advantage compared to 2-component PU foaming:

If so, make an appointment with us. Our team would be pleased support you in a personal discussion or by e-mail.